Introduction

May 23, 2022. We click the “send” button that releases the newsletter announcing the launch of our male denim pants. At first, nothing revolutionary for a clothing brand. Except that these pants are a little bit special: the dreaded crotch blow out should appear later than on other jeans. To get there, we have worked for three years, invented a new wear test with our laboratory and finally developed our own fabric in the Vosges mountains.

Let us walk you through the process.

Crotch blow out: a denim’s plague

Before starting the manufacturing of our jeans, we sent you a small questionnaire: « What is usually the problem with your jeans?” And to a simple question, a simple answer: the problem is the crotch blow out.

That’s right: when you walk, your thigh rubs against the other thigh (or rather: against the bottom of your buttock), which weakens the fabric of the jeans and eventually perforates them.

To make our own, we first had to understand why some jeans get holes faster than others. Our first reflex: skim the hundreds of web articles dedicated to crotch blow out. But on the websites and forums we visited, nobody agreed: fabric that is too thin, presence of elastane, bad cotton quality, cut that is too tight, seams that are too thick, humidity due to perspiration…

And then one day, we had a revelation: what if the truth about holes in jeans lies… in chino pants. We’ve been selling our Loom chino pants since 2019, and we know one thing for sure: crotch blow out is not a thing with chino pants, and the few customers who have experienced it are heavy bike or motorcycle riders – in other words, our chinos don’t have holes from the friction of walking.

So the question was simple: what are the specifics of jeans versus chinos that could explain the crotch blow out with jeans?

Looking for the explanation

This question allowed us to eliminate most of the hypotheses found online:

- Jeans have holes because they are too thin: no, chinos are generally thinner than a pair of jeans.

- Jeans have holes because they are too tight in the thighs: no, in the crotch area, jeans and chinos are more or less cut the same way.

- Jeans have holes because of exogenous factors (moisture due to perspiration, tension when moving…): no, unless proven wrong, we do almost the same thing with jeans as with chino pants.

- Jeans have holes because they have elastane: no, like most jeans, most chinos contain some percentage of elastane for comfort.

- Jeans have holes because their cotton is of poor quality: no, there is no reason why the cotton fibers used in jeans should be shorter or of lower quality than those used in chinos.

- Jeans have holes because their yarns are of lower quality: no, even if it is true that a part of the jeans were woven since the 70’s with « open-end » yarns (cheaper and maybe less resistant to abrasion), 95% of the jeans are nowadays woven with traditional « ringspun » yarns, most probably like chinos.

We were left with only two hypotheses to test:

Hypothesis #1: The double seam. The inner leg seam of jeans is thicker than that of chinos – a double seam could cause more intense chafing than with chinos.

Hypothesis #2: Roughness. The threads of jeans are thicker than those of chinos: their fabric is therefore rougher. When one thigh rubs against the other, it’s a bit like a piece of sandpaper rubbing against the fabric.

Our lab tests

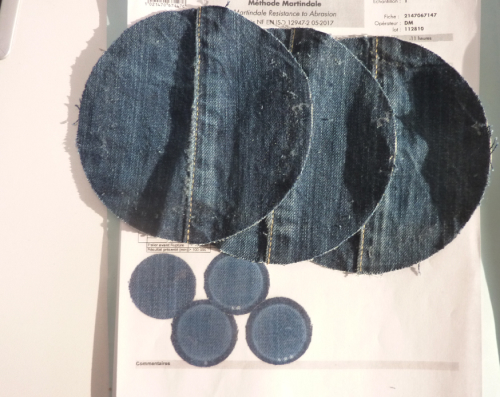

To test our hypotheses, we decided to simulate this friction in a laboratory, with a test called « Martindale »: a machine rubs the fabric until a hole appears. The result is counted in number of cycles: the higher the number, the more resistant the fabric.

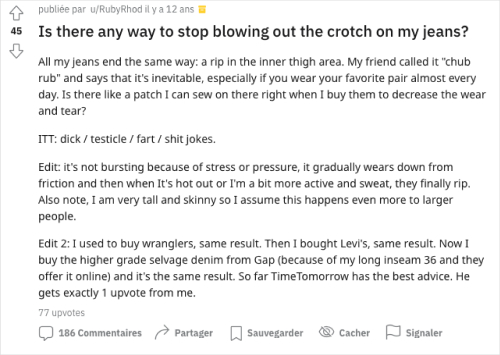

To begin with, we wanted to check that the Martindale test simulates what happens in real life: we sent pieces of jeans fabric and of chino fabric to our lab to check that, in lab conditions, jeans get holes faster than chinos as well.

But when we received the results, we were surprised: in the lab, the jean fabric had lasted twice as long as the chino fabric (100,000 vs. 50,000 cycles). The opposite of what happens in real life…

So we thought for a second: this Martindale test cannot simulate what really happens to the crotch, since it uses the same standard « abrasive wool » to rub against the fabric. But when you walk, the fabric rubs against itself! We called our lab and came up with another type of test, where we replace the abrasive wool with the fabric itself. After some adjustments on the right pressure level in the machine, this test will answer to the sweet name of « Fabric abrasion resistance Martindale method modified fabric against fabric, pressure 12 kPa ».

A few days later, the results of the new test were in:

Bingo! We had found a laboratory test that simulates what happens in real life: chinos are (at least) three times more resistant than jeans to friction: 100,000 vs. 35,000 cycles.

So we could move on to the next step: testing our two hypotheses to find the cause of these holes on your jeans.

To test the first hypothesis (the double sewing of the jeans), we replaced the single fabric with a fabric with sewing on the Martindale machine… When we received the results, we realized that it did not change anything: the sewing does not weaken the fabric. Suspect found not guilty.

By elimination, only one suspect remained: roughness. To check this hypothesis, we decided to have several types of jeans tested: smooth jeans and rough jeans. And all the results confirmed that the thicker and rougher the jeans, the faster they get holes:

- The thinnest jeans we found (Muji brand) resist very well: they exceed 100 000 cycles.

- Thicker raw jeans (Uniqlo brand) do not resist very well: 35 000 cycles. On the other hand, when we make the fabric less rough manually with sandpaper before sending it to be tested, it holds much better and also exceeds 100 000 cycles!

- Jeans that are quite rough because of the use of an « open end » thread do not hold very well: only 16,000 cycles.

- Raw jeans and their washed equivalent (and thus less rough): the first one holds 70 000 cycles, much less than the second one, which breaks at 100 000 cycles.

In short, after several months of testing (and a few thousand euros spent…), we had identified the culprit: roughness. Exactly the opposite of what we would have thought intuitively: thick cowboy jeans are more likely to experience crotch blowout than thin jeans.

Then, we just had to develop our fabric.

We had two options:

- Test a lot of existing fabrics from suppliers and choose the best one.

- Develop our own fabric: more uncertain, slower, more expensive… but with the hope of creating a fabric perhaps more powerful than those that already exist!

You can already guess what we chose, right?

Going to Les Vosges

Finding a factory that would agree to make such a development with us was not supposed to be an easy ride. It takes time, money and we are not Levi’s: at first, we hoped to order max 10,000 meters of fabric per year, that is to say a little more than 100,000 euros… Economically not very interesting for a manufacturer.

However, Tissage de France, the factory in the Vosges region of France that manufactures the jeans for the brand 1083, immediately agreed to work with us on this project. The deal was: we share the development costs, and if it works, the factory will be able to reuse everything we learned together in other projects with other customers (this is what we had already done successfully when we developed our cotton socks).

(six clues in this photo will help you find the year of our visit).

To develop a denim fabric that is not too rough but still keeps a nice hold, we decided to weave:

- A rather thin denim (12 oz weight).

- With a ringspun yarn (softer than its open-end equivalent).

- And double-twisted (two threads twisted together for more resistance and hold).

- All in organic cotton, of course.

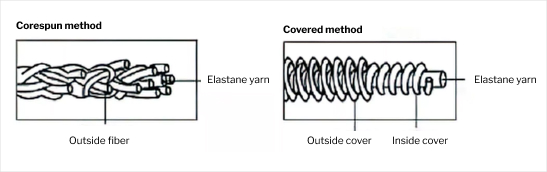

But we didn’t stop there: we also wanted to solve the 2nd big problem that came up in our questionnaire: the fact that jeans get loose over time. For that, instead of spinning the elastane at the same time as the cotton fibers (the classic method known as « corespun »), Denis, the director of the factory, recommended that we twist two cotton threads around a filament of elastane (the « covered » method, more expensive but seemingly more effective).

It took us a few tries to make the final adjustments (especially on the size of the elastane thread), and finally: we managed to weave a denim that holds up. If you want proof:

- With the test we invented (fabric vs. fabric abrasion), our jeans exceed 200,000 cycles! That’s more than any other jeans we’ve ever tested.

- With the residual deformation test, the residual elongation after one minute is only 1.8%, which is quite honorable: on the six other jeans we tested, only one did better.

Yes, but if it’s to make a solid but ugly denim, there’s not much point, is there? Good news, our fabric looks like this:

We’ve got it

With the development of the fabric, we had done the biggest part of the job. Because for the manufacturing part, we knew who to turn to: 5D, our Portuguese factory specialized in pants (and which manufactures for many great French brands).

Compared to our fabric, our specifications were quite simple… We wanted:

- A semi-slim fit.

- Pockets deep enough to fit your phone and strong enough for your keys not to tear them.

- A zipper fly, because it’s more practical and it washes out more nicely.

- A first pre-wash on the raw denim, so it doesn’t shrink at home.

- Reinforced belt loops.

After some back and forth on the cut, we had our jeans! Beautiful, comfortable, and solid. It was ready for production.

|

Sidenote: Let’s talk about that price |

|---|

|

These jeans are sold for 100€. Yes, it’s not cheap… but it’s not that expensive: First of all, the development phase cost us a lot of money: between the lab tests, the development of weaving tests and the back and forth on the prototypes, it cost us about 10,000 euros (not counting our own work time). The fabric costs about 15 euros/meter to produce, which is almost twice as expensive as the classic made in Italy fabrics: organic cotton, ringspun, double twisted yarns, elastane yarns with a sheath rather than corespun, made in France… Our ethics and our quality choices have a cost. The confection is carefully made in Portugal, with wages much higher than 95% of the jeans on the market, mostly made in Asia or North Africa. But as we don’t make any collection, nor sales, nor ads, and as our shareholders don’t push us to make a big margin (more details here – if you can read French), we sell it for « only » 100 euros (for the moment – this price could change with the inflation on energy and raw materials). |

Resistant, but not indestructible

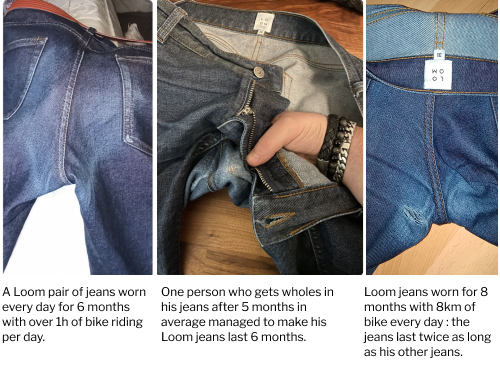

It’s been almost a year since we launched these jeans: we’re starting to have some hindsight on how they age. First of all, the people who bought them seem very satisfied: they are rated 4.7/5 by more than 100 people, which is really great.

But will these jeans resist crotch holes for eternity?

No.

Out of more than 2,000 jeans sold, we have already had three cases of crotch blowouts: people who regularly ride bikes or motorcycles. Now, we designed these jeans to resist well to « thigh against thigh » rubbing… but they will not be much more resistant than other jeans for « thigh against saddle » rubbing (even if, each time, the concerned customers told us that their Loom jeans pierced less quickly than the other ones they wear).

And even for the rubbing related to classic walking, if they will probably resist longer than the average, it is very likely that they will also end up with a hole one day: in a nutshell, like any garment made of natural materials, these jeans will eventually wear out.

Could we make even more resistant jeans?

Probably, but then we would have to use more synthetic materials: to make a stronger garment, it is often enough to replace cotton by polyester. But it is less pleasant to wear, it retains odors and especially, for the environment, we think that fashion must get rid of plastic (we talk about it here, in English).

But are these holes really that bad?

Not really. Because like all clothes, jeans can be repaired.

In fact, jeans are even easier to repair than other clothes.

First, their alternating blue and white threads make them visually inconsistent… so repairs can be almost invisible. To repair a crotch blowout, you can add a patch of fabric inside the jeans and then sew it with a thread of the right color… And here is the result:

Moreover, even if the repair shows a little, it’s not so bad: denim experts consider that what makes the beauty of a pair of jeans is the mark of what it has been through. Washing, tears, repairs… In short, the « patina » are all scars that give it value – and that many brands try to reproduce artificially in the factory.

Conclusion: let’s not focus on the wrong fight

If our jeans will eventually break down and repair relatively easily, was it worth the research?

We hope so: if the first holes in the crotch appear even one or two years later than with your other jeans, that’s still a win. Also, to develop these jeans, we had to understand the science behind the clothes. And that really motivates us. Finally, supporting French factories by doing R&D with them is also our most exciting and higher mission.

But we have to keep a clear head: indestructible clothes don’t exist… and they never will. The most important thing to do to keep a garment for a long time is not its inner quality: it is above all how we take care of it. The clothes of our grandparents were probably much less resistant than today’s. Yet they kept them much longer. Because they knew how to maintain them, repair them, mend them.

We must now collectively re-learn how to take care of our clothes. Putting on a towel before eating tomato pasta, shaving the pilling from our sweaters or socks, delicately washing our woolen sweaters, sewing on our buttons, repairing tears… and mending the holes in the crotch of our jeans.

In short, clothes that last a long time are above all clothes that age well.

Buy less clothes, take care of them.